Wiped film (WF) distillation is intended to be operated as a continuous process. Continuous processes have the advantage of running nonstop. Oil is fed in one end and product comes out the other end.

But wiped film for cannabis oil is being operated as a multi stage batch process which is on the other end of the spectrum from continuous operation.

Here’s how a typical wiped film is being operated for cannabis oil:

Step 1. Decarb the oil

Step 2. Strip every bit of solvent from the oil

Step 3. 1st WF pass (remove volatiles from main body) STOP

Step 4. 1st cleaning run STOP

Step 5. 2nd WF pass (remove terpenes from main body) STOP

Step 6. 2nd cleaning run STOP

Step 7. 3rd WF pass (further enrich main body cannabinoids) STOP

Step 8. 3rd cleaning run STOP

Instead of a continuous operation, there are actually 8 separate batch processes needed to purify the oil with a wiped film. How is that continuous distillation?

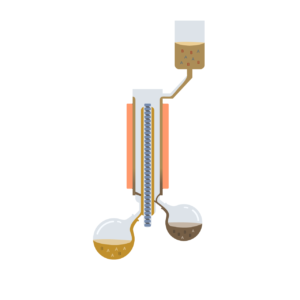

Spinning band distillation was designed as batch process. It can purify cannabis oil in a single pass to higher purity then can be achieved by wiped film or short path.

What some manufacturers are calling continuous distillation is just a more complicated batch process.

Any processor knows that variation in feed stock impacts not only the yields but also the specific compounds extracted. Whether you have a terpier batch, a waxier batch, or an incredibly clean batch affects the distillation process. Because distillation is targeting highest % cannabinoids, the compounds present will absolutely change the distillation performed. This adds to the complexity of a continuous operation if your parameters are changing during your run!

Pesticide contamination is an issue that is slowly being resolved on the west coast of the US, but an issue that the east coast is largely still figuring out. If operating continuously, what could a small contaminated batch do to liters upon liters of distillate.

Comments are closed, but trackbacks and pingbacks are open.