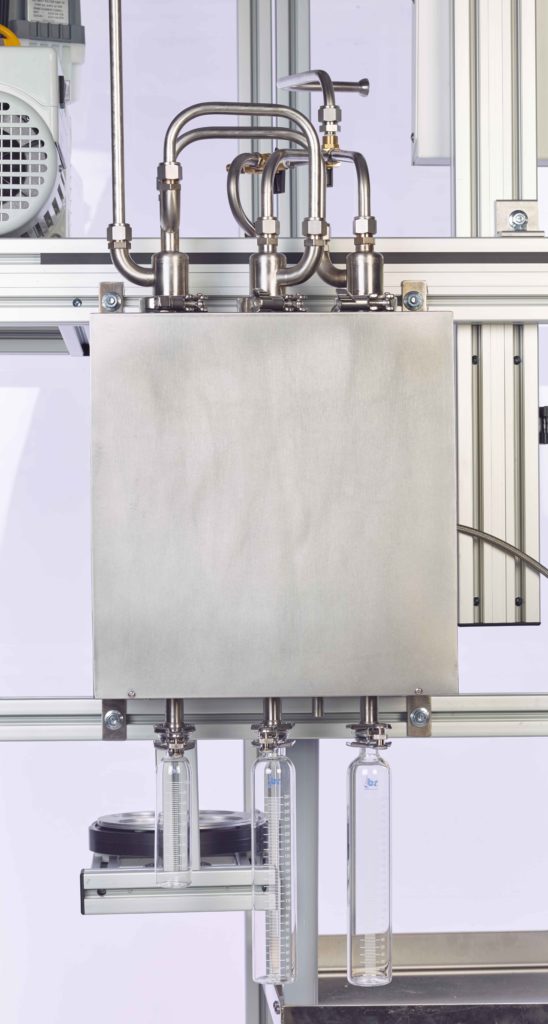

B/R is the only company in the cannabis industry using a stainless steel cold trap.

Why would you use glass (an insulator) as a material for a cold trap? It is horrible at transferring heat/cold.*

The condensing surfaces in the B/R cold trap are made of stainless steel which has 10 times the thermal conductivity of glass. Higher thermal conductivity means the cold trap is much better at preventing vapors from getting by. The receivers are glass for easy viewing of the contents.

Multi-Cold-Trap

To condense even more vapors, the B/R cold trap features 3 trapping positions. 3 cold traps is better than one, right? By having multiple traps for each section the cold trap does a better job of trapping volatile components such as mono-terpenes.

Cold Trap Cooling

The cold trap can be maintained by using a slurry (dry ice and methanol/isopropanol/acetone) or using a cold finger. Polyscience makes our -100 C cold fingers. These normally operate at about -80C. We recommend the cold finger because it eliminates the need to source and replenish dry ice.

Remove receivers without stopping

The cold trap is equipped with valves so that the operator can remove and replace the cold trap receivers during distillation. When you’re done collecting terpenes you can quickly remove the terpene filled receivers and replace them with clean/dry receivers. Then you can go down to maximum vacuum without pulling terpenes into the vacuum pump.

By protecting your pump, you not only extend the lifetime, but you are also able to achieve a deeper vacuum when you need it.

Removing volatile compounds from the system before distilling your main body will help create a deeper vacuum and therefore allow you to distill at lower temperatures

*Heat Capacity

Heat capacity is the energy it takes a material to change in temperature by 1 K. Heat capacity is denoted by the lower case ‘c’.

mass*heat capacity*change in temperature = energy

or

c = 0.75 J/g K for pyrex (borosilicate)

c = 0.5 J/g K stainless steel

Let’s say your cold trap weighs 1000 g. That means we multiply these heat capacities by a mass of 1000 g

to get 750 and 500 J/K. Now let’s say you need to cool the vapors by 40 C (K and Celsius values have the same “spacing” between units, and we are only concerned with the change in temperature, not the temperature itself). 30,000 J vs. 20,000 J! 1 joule per second is equal to a watt.

In other words stainless is 33% more effective for your utilities alone!

Comments are closed, but trackbacks and pingbacks are open.