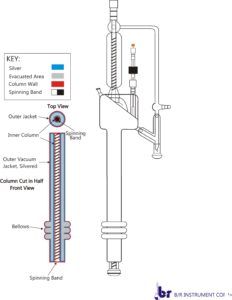

The spinning band distillation column has a vacuum jacket (like a thermos) to minimize heat loss through the distillation column wall. The evacuated jacket disrupts heat conduction due to the lack of air (only 10-7 mmHg !).

The vacuum jacket has a silver coating on the inside to reflect any radiant heat. Combined with the vacuum jacket, most of the heat lost is prevented!

This type of vacuum jacket is sometimes called an adiabatic jacket. Adiabatic meaning that no heat enters or leaves. A more adiabatic column means a more efficient column. Silvering reduces start up times and increases distillation rates.

If your THC/CBD is condensing before it can reach the top of the column, it will not be distilling over into your receiver.

Silvering the vacuum jacket is as much an art as it is a science. The glass surface must first be prepared. Even the smallest of impurities on the glass surface causes the silver to peal or be discolored. Temperature, humidity and other parameters must be carefully controlled to get a uniform reflective surface.

After silvering the vacuum jacketed column is placed in a 200 C oven and connected to a diffusion pump overnight. This process ensures that any volatile residue is eliminated before the vacuum jacket port is sealed with a torch.

Comments are closed, but trackbacks and pingbacks are open.