True boiling point distillation distills crude oil from the initial boiling point up to 370-400 °C. D2892 is the ASTM test number. It is most commonly used to test crude oil and crude oil blends. It is sometimes used to distill condensate although that is outside the scope of D2892.

True boiling point distillation distills crude oil from the initial boiling point up to 370-400 °C. D2892 is the ASTM test number. It is most commonly used to test crude oil and crude oil blends. It is sometimes used to distill condensate although that is outside the scope of D2892.

The distillation typically takes place in 3 pressure sequences, atmospheric, 100 mmHg vacuum, and 10 mmHg vacuum. Although it is permitted to go down as low as 2 mmHg.

| Pressure | Temperature Range |

| Atmospheric | Initial Boiling Point – 200° C |

| 100 mmHg | 200 °C – 300 °C |

| 10 mmHg | 300 °C – 370 °C |

The reflux ratio should be 5:1 for all pressure sequences. It is permitted to be 2:1 for the lowest pressure level if all parties agree.

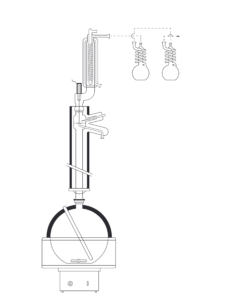

A variety of distillation column packings are permitted including Pro-Pak, Heli-Pak, wire mesh and perforated plates.

| Packing Type | Pro-Pak | Heli-Pak | Wire Mesh | Perforated Plates | ||||||

| Column Diameter |

25 mm

|

36 mm

|

50 mm

|

70 mm

|

25 mm

|

50 mm

|

25 mm

|

50 mm

|

25 mm

|

50 mm

|

| Packed height |

57 cm

|

60 cm

|

80 cm

|

91 cm

|

31.5 cm

|

48 cm

|

72 cm

|

99 cm

|

25*

|

23*

|

| Minimum Sample Size |

1.2 L

|

2.3 L

|

6 L

|

15 L

|

0.575 L

|

3.3 L

|

0.7 L

|

4.9 L

|

1 L

|

4.6 L

|

| Maximum Sample Size |

4.8 L

|

9.2 L

|

24 L

|

60 L

|

2.3 L

|

13 L

|

2.8 L

|

19.4 L

|

4.2 L

|

10.4 L

|

*perforated plates

Comments are closed, but trackbacks and pingbacks are open.