Crude Oil Dehydration

D2892 requires that crude oil contain less than 0.3% water. But many crude oils contain more than 0.3% water and cannot be tested until they are dehydrated.

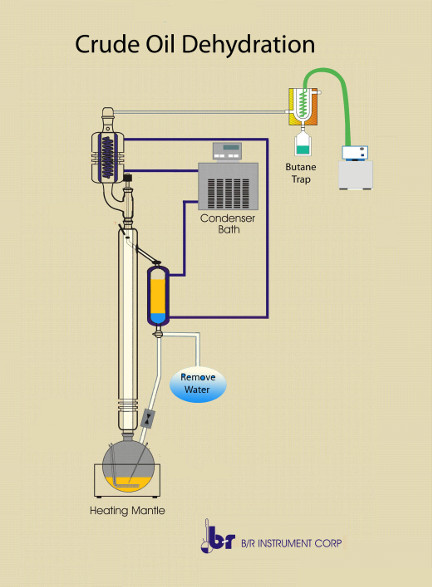

The B/R crude oil dehydration system performs a quick, atmospheric distillation. The light portion of the crude oil and the water are distilled into a chilled receiver shaped like a funnel.

Two phases are formed with water on the bottom and the light crude oil fraction on the top. Chilling of the receiver prevents any loss of the volatile components. Butane is collected separately in special butane traps.

When the process is complete, it automatically stops. Water can be drawn off the bottom through a valve. The light crude oil fraction is returned to the boiling flask (after cooling)

Now the crude oil is dehydrated and D2892 can be successfully performed.

Key features of the B/R Crude Oil Dehydration System

- Complies with ASTM D2892 Annex X1 , Dehydration of Crude Oil

- Dehydrate crude oil sample sizes 50 ml up to 50 liters

- Stainless Steel construction is rugged, perfect for handling samples with high water content

- Receiver is jacketed and temperature controlled to prevent evaporation

- Fully automatic process.

Why can’t I perform D2892 on a “wet” crude oil?

Distilling “wet” crude oil is difficult and yields poor quality results.

Water in crude oil causes:

- Uneven boiling and “bumping”

- Formation of azeotropes

- Vapor Temperature instability

ASTM D2892 requires crude oil to have less than 0.3% water content.

Water can exist in several forms:

- Some water is so called “free water” and forms a separate phase at the bottom because it is heavier than most crude oils.

- Some water can be emulsified in the crude oil and cannot be separated by filtration.

- Some water can be chemically bound in complexes.

The B/R dehydration system successfully separates all types of water contained in crude oil regardless of the form. It fully complies with ASTM D2892 requirements.